If you are running a solar photovoltaic (PV) plant, then you know how much data it can yield. A solar PV plant has a lot of moving parts, and it is crucial that you have the ability to collect any significant information for later use. A data acquisition system (DAS) can help with this. An effectively utilized DAS can make or break your operation, which is why Nor-Cal Controls has created this list of best practices to consider when trying to get the most out of your DAS.

Ability to Scale with the Industry

One of the most crucial attributes of any data acquisition system is scalability.

It is crucial that you adhere to current industry standards when utilizing a DAS. Solar energy is a rapidly growing industry that is evolving and becoming more advanced each and every day. A DAS should be developed with the latest industrial advancements taken into account and be able to scale alongside the shifts in the industry.

A DAS that is not adaptable is a DAS that is ineffective and unreliable.

Open architecture is a design method that makes the adding, upgrading, and swapping of the software's components easy and intuitive. An open architecture DAS can go a long way in helping your operation scale without any unnecessary growing pains.

A rigid, proprietary based, "black box" (non-upgradable or scalable) DAS may seem like an enticing option for small-scale solar energy plants, as these smaller plants might not require the additional features offered by an open architecture system, but because future growth is a highly likely possibility within the solar industry, scalability should always be taken into consideration when choosing a DAS.

A proprietary based DAS will only waste time and money in the long run.

The only purpose of a DAS is to collect data gathered from your solar plant. The DAS itself is limited in terms of being able to do anything with that data control-related. If your solar plant begins to grow, and information processing needs to become an automated task, your DAS will need to be upgraded to a SCADA system or some kind of SCADA/DAS hybrid to allow for control functionality.

If you invest in a proprietary acquisition system that cannot be upgraded when you first deploy your energy production plant, then you will have to start from scratch when creating a more advanced system in the future, so it's best to plan ahead.

Nor-Cal Controls specializes in commissioning open architecture, scalable data acquisition systems and SCADA systems. Take a look at all of the different energy solutions that we offer.

Support Different Hardware Configurations

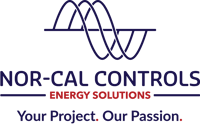

A data acquisition system is just that: a system. It is a collection of moving parts that work together to collect different kinds of information from your solar PV plant. In order for your DAS to accurately collect all the different types of data, you will need to employ different types of hardware. For example, a data logger acts as a central hub which pulls information from all of the meteorological (MET) stations, inverters, meters and/or trackers located around your plant.

Having a DAS that supports multiple types of hardware configurations is important. Keep in mind that having more hardware at work in your plant will mean higher costs for both initial purchases and ongoing maintenance.

How important is data collection to you?

Is it important enough that you would consider investing in extra hardware? If so, you will need to ensure that your DAS supports the necessary hardware required. If your DAS isn't compatible with certain types of hardware, then your plant data collection will be limited.

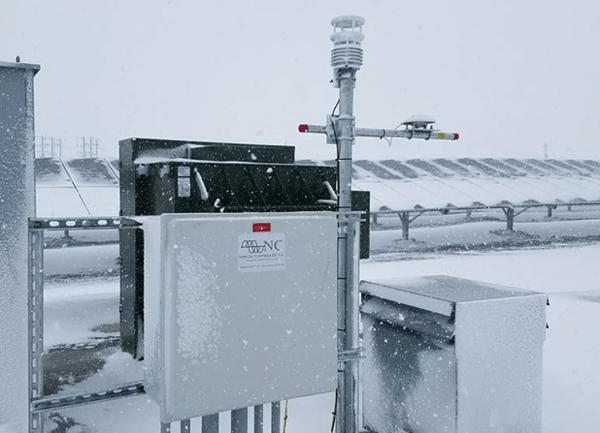

Meteorological Station Sensors

Some of the most important pieces of hardware to any solar energy plant are your MET station sensors. Since solar plants pull energy from the sun, being privy to weather patterns and upcoming events is crucial to maximizing your plant's ability to generate energy from the sun.

Size is also an important factor in determining how many MET station sensors you need, as well as how powerful they will need to be. According to the North American Electric Reliability Corporation (NERC), up to two MET stations is sufficient for a plant that is less than twenty megawatts.

Your DAS needs to be able to support the number of MET stations required. If it does not, then you will need to invest in another option or upgrade the one you have. This is another reason why scalability and open architecture in your DAS is important.

Read this article to learn more about MET stations, how they work, and what measurement requirements are for solar sites. Also, take a look at the fully-customizable Tahoe MET Stations that we offer here at Nor-Cal.

Cabling Considerations

In order for the data logger to be able to pull information from the different hardware at work collecting information throughout your plant, the type of network cables you’re going to use needs to be considered. This generally comes down to two options: ethernet and fiber.

The size of your plant and the distance between the DAS and the field hardware are important factors to consider when it comes to choosing a cable option. For most commercial and industrial or distributed generation solar PV installations, the field hardware and the DAS enclosure are within three hundred feet of each other. If this is the case for your plant, then ethernet is a great option.

If your field hardware and DAS enclosure are more spread out, for instance if you have a larger-sized plant, you may need to invest in fiber optic cabling in order to properly collect the data you need. Fiber is more expensive than ethernet cabling, but for distances past 2km it is essential to keep the data flowing reliably.

If you are looking to upgrade, revamp, or completely install a new DAS or SCADA system, then visit Nor-Cal Controls to learn how our advanced, state-of-the-art energy solutions can maximize the efficiency and productivity of your solar photovoltaic plant.