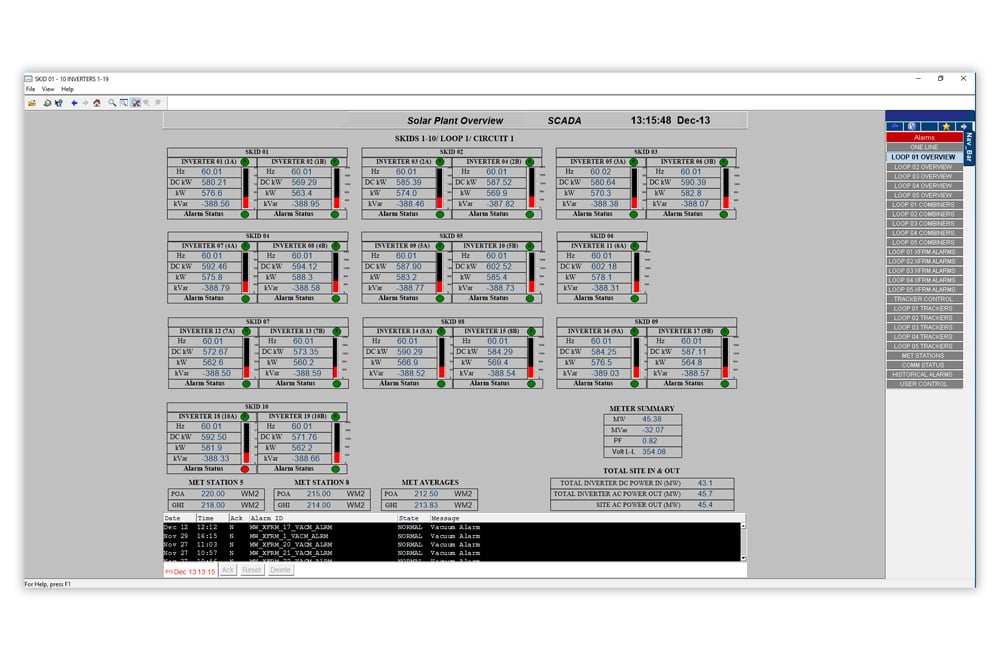

A Human Machine Interface (HMI) is a user interface that allows a person to interact with a system, machine or device. While this sounds complicated, it is simply a computer screen that displays data. If you’ve ever used an ATM to "ask" the machine to give you cash, you have used an HMI.

HMI software serves multiple purposes for a solar facility. It allows operators to:

- View data from inverters, trackers, substation devices and other solar facility components

- View alarms from these devices

- Check power production from inverters

In a Supervisory Control and Data Acquisition (SCADA) system, the HMI is also the means by which the operator gives commands to the Power Plant Controller (PPC).

When is HMI software typically required?

We recommend using an HMI software for all solar PV projects. However, the type of HMI—local/onsite or remote—may differ depending on the project size.

Cloud-based HMI programs provide remote visibility to a site and can be used for any size of project. For large utility scale projects (greater than 10 megawatts), it is recommended to have an individual, standalone HMI onsite in order to view all the field devices.

For smaller projects within the Commercial and Industrial (C&I) sector (5 to 10 megawatts or less), typically there is not a set requirement to have an individual onsite HMI. Operators may choose to install a system that can look at a portfolio of smaller sites using a remote cloud-based HMI program. This solution can be more cost-efficient for small sized projects that do not require remote and onsite visibility.

Typical HMI Requirements for Solar PV—DAS and SCADA

Data Acquisition Systems (DAS) and Supervisory Control and Data Acquisition (SCADA) are two different systems for assessing site performance and identifying operational issues. Both pull in data from networked site devices and equipment. SCADA adds the ability to control the devices through the use of an onsite controller—usually a Programmable Logic Controller (PLC). SCADA systems also include dedicated a historian server, which stores the acquired data.

For a comprehensive look at the differences between these two systems, we invite you to read our DAS vs. SCADA article. Here, we will cover the differences in HMI requirements.

HMI Requirements for DAS

DAS is typically used for small DG/C&I projects and other smaller sites, such as 1 or 2 megawatt facilities. Most DAS setups are simple, consisting of networking equipment and a data logger or data concentrator. Not all DAS setups include an HMI.

When they are used, HMI platforms for DAS are also simple. The purpose of the HMI is to monitor every device that's available in the field. The typical screens include:

- An overview screen that shows how the plant is operating as a whole

- A detailed screen that allows you to view individual field devices such as inverters and trackers

- A screen that shows the status of substation devices (are the breakers open or closed, are the breakers generating any alarms, etc.)

HMI Requirements for SCADA

SCADA systems are typically used for larger facilities, to help operate and manage the plant efficiently. SCADA systems can be locally installed on onsite servers or use remote cloud-hosted servers.

SCADA is far more complex than DAS, allowing for supervisory control of plant devices as well as the ability to look at stored data. SCADA software can generate alarms and send alerts to operators via SMS or email when something needs attention.

This all requires a more robust HMI platform, with screens to control the plant devices. If an operator needs the plant to produce a specific amount of power, for example, he or she can use the HMI to interface with the system, type in commands, and "ask" the plant to take certain actions.

Typical screens include:

- Plant overview

- Trends, charts and reports

- Alarms

- Inverter and tracker details

- Substation Overview

- Site Controls overview

- MET station screens

At Nor-Cal Controls, we also create custom screens to meet owners' specifications or EPC requirements.

The HMI and Plant Controls

How does the HMI work with logic development software to enable control?

As we touched on earlier, SCADA systems use an onsite controller—usually a PLC—to control networked site devices.

A PLC is a physical device (hardware) that controls devices or processes based on pre-programmed, closed-loop logic. At Nor-Cal Controls, we predominantly use PLC controllers manufactured by SEL, GE or Allen-Bradley. We write all of the control logic in the PLC.

Site operators use the HMI platform to enter their commands. The SCADA software then communicates with the controller, which inteprets these commands and passes them through to the field devices so that the plant can accordingly act as one resource.

How does the operator know how to enter the commands? At Nor-Cal, we provide a control narrative that includes a list of preset commands. It describes everything that's been programmed and all the commands to use to operate the site.

How does the HMI work with the plant controller to meet requirements from the utility?

Utility scale plants have Power Purchase Agreements (PPAs) and Interconnect Agreements (IAs) that require the ability to curtail or to maintain certain line voltage. The utilities expect their generating plants to operate within certain parameters, in order to support a stable grid.

Plants meet these parameters by regulating active and reactive power through these controls:

- Real Power Control (Curtailment)

- Reactive Power Control (Automatic Voltage Regulation (AVR), Power Factor, MVAR)

In some cases, utilities also require frequency droop and voltage droop controls. For a more in-depth look at these power plant control requirements, take a look at our article, Power Plant Controllers: Typical Control Requirements for PV Sites.

The HMI is the means by which the plant operator can communicate these parameters or setpoints for the plant. All he or she has to do is enter the commands. The logic that is written in the PLC automatically takes care of the calculations and adjustments to meet the parameters.

Plant Monitoring & Alarms

One of the main functions of an HMI at a solar facility is to display alarms.

Is separate software needed to generate alarms?

This depends on the SCADA software used. Some of the SCADA software packages have inbuilt alarming capabilities, but supplementing them with additional software allows for greater customization and better alarm management.

For example, we typically use a GE-provided software package called CIMPLICITY for our SCADA systems. CIMPLICITY within itself can generate alarms, but doesn't have the ability to send out alarm messages. In order to do that, and to have better control over alarms, we add a third party software package called WIN-911.

Ignition is another SCADA software package we use often. This software comes with different components, called modules. Sending out alarm messages requires the purchase of the alarm management module.

What are the standard alarms used in HMI?

System alarms can be categorized by their origin and their priority/severity. We'll touch on the basics here. For more on alarms and what to do about them, read our SCADA Troubleshooting Basics.

1. SCADA System Alarms

Main SCADA system alarms include power supply notifications (activation of the SCADA UPS and backup power supply) and network issues such as loss of IP connection. The most prevalent SCADA alarm is 'Device Down.' This alarm occurs when a device is no longer communicating on the network.

2. Substation Alarms

Substation alarms involve communications to the protection devices, revenue meters and building environment. Also included in this group are breaker status alarms (under-voltage trip, over-voltage trip, under-frequency trip, over-frequency trip). There are also transformer alarms for oil level, winding temperature, and liquid temperature.

Substation alarms are high priority and require immediate action. Any alarms on the transformer are very critical.

3. Field-Related Alarms

These alarms involve the PV arrays, inverters, tracking systems, weather stations and other field equipment. The alarms available for these devices depend on the manufacturer. Each manufacturer has its own manual that lays out the available alarms. The manufacturer also provides recommendations for the priority set on the alarms as to which are critical and which are not. The O&M team will also provide input, based on their preferences.

Alarm Priority

At Nor-Cal, we work with customers to determine the level or priority (low, medium, high) they want assigned to each alarm point in the system—for the inverters, tracker controllers, combiner boxes, transformers, MET station sensors, etc. Different customers make different choices. We can then go into the alarm software and set the priority/severity for each point.

Here are examples of alarm priorities in a typical SCADA setup:

- High Priority: Warning of potential equipment failure, loss of production, and deviations from the specified voltage and power, due to a serious fault. Requires immediate attention.

- Medium Priority: Maintenance alarms not requiring immediate attention, but will need attention soon.

- Low Priority: Informational alarms not requiring immediate attention.

Alarm Flows

Alarm notifications display on the HMI screen. However, some alarm notifications also need to be "pushed out" to specific people via email or SMS. As part of the setup process, we work with customers to decide who should receive these alarm messages, and how. These are called alarm flows.

For example, an inverter alarm probably doesn't need to go to the Director or Operations for the plant. If an alarm comes from a transformer or the plant has tripped offline, that's a critical situation that many people need to know about, right away. A customer might prefer email for lower priority alarms, but SMS (text message) for higher priority alarms that require a quick decision.

Contact us for a turnkey control system that's customized to your solar PV project needs.

Nor-Cal has many years of project experience (over 7GW worth of successfully commissioned projects across the United States to date), meaning we can help you determine the best system for your solar PV project. Our turnkey solutions are open source, readily scalable, flexible, and completely customized to handle your current and future needs.

Schedule a call with us today to learn more.